MAD ABOUT POLY

BLK-OUT and The BLK-OUT Foundation is dedicated to raising awareness of the problems with plastic-based polyester, and warn you of their polyester’s inept dye retention.

Poly & the planet

-

The production of one kilogram (2.2 pounds) of polyester emits approximately 5.5 kilograms (12 pounds) of carbon dioxide (CO2) into the atmosphere. To put this into perspective, producing polyester for just one t-shirt generates emissions equivalent to driving a car for about 20 miles.t goes here

-

Polyester production is highly energy-intensive. It takes almost three times more energy to produce polyester compared to cotton. The energy used in the production process primarily comes from fossil fuels, contributing to the depletion of non-renewable resources and greenhouse gas emissions.

-

It takes a substantial amount of water to produce polyester. On average, about 70-75 liters of water are required to produce one kilogram of polyester fabric. This significant water consumption contributes to water scarcity and puts pressure on water resources, especially in regions already facing water stress.

-

Polyester is derived from petroleum, a non-renewable fossil fuel. By relying on petroleum-based feedstocks, the production of polyester perpetuates our dependence on fossil fuels and contributes to the extraction and depletion of finite resources.

-

When polyester garments are washed, they shed tiny microfibers into the water. These microfibers are essentially plastic particles that are too small to be captured by wastewater treatment plants. As a result, they end up in rivers, lakes, and oceans, contributing to microplastic pollution and posing a threat to marine life and ecosystems.

-

Polyester is a non-biodegradable material, meaning it does not break down easily in the environment. When polyester garments are discarded, they contribute to the growing textile waste problem. In landfills, polyester takes a long time to decompose, occupying valuable land space and adding to the overall waste burden.

Mankind’s use of plastic has impacted daily lives and environments of people and animals across the globe, and polyester is no different.

Source: The UN’s Plastic is Forever exhibit

-

Polyester doesn't like water very much. It resists water, which makes it hard for dyes that are carried in water to penetrate and stick to the fabric. Imagine trying to paint on a surface that repels water—it's not easy to make the paint stick!

-

Polyester fibers have a smooth surface that doesn't provide many places for dyes to attach. Unlike natural fibers like cotton or wool, which have tiny hooks and crannies for dyes to grab onto, polyester doesn't offer many good spots for dyes to bond with. This leads to our greatest warning: polyester threads (see below).

-

Polyester garments require high temperatures (at least 180F) in order to dye properly. Many natural fibers are heat sensitive, limiting the of materials that can polyester can be dyed with effectively.

-

Polyester is made from synthetic materials, and its fibers are tightly woven together. This makes it more difficult for dyes to penetrate the fabric and form a strong bond with the fibers compared to more porous natural fibers.

-

The chemical structure of polyester doesn't naturally attract dyes like some other fibers do. Polyester lacks certain chemical groups that readily bond with dyes, making it harder for the dye molecules to stick to the fabric.

-

Polyester also faces challenges in maintaining the color over time. While dyes may initially adhere to the fabric, polyester can be more prone to fading or losing color intensity compared to some other fibers.

Poly & our process

Polyester thread & black dye

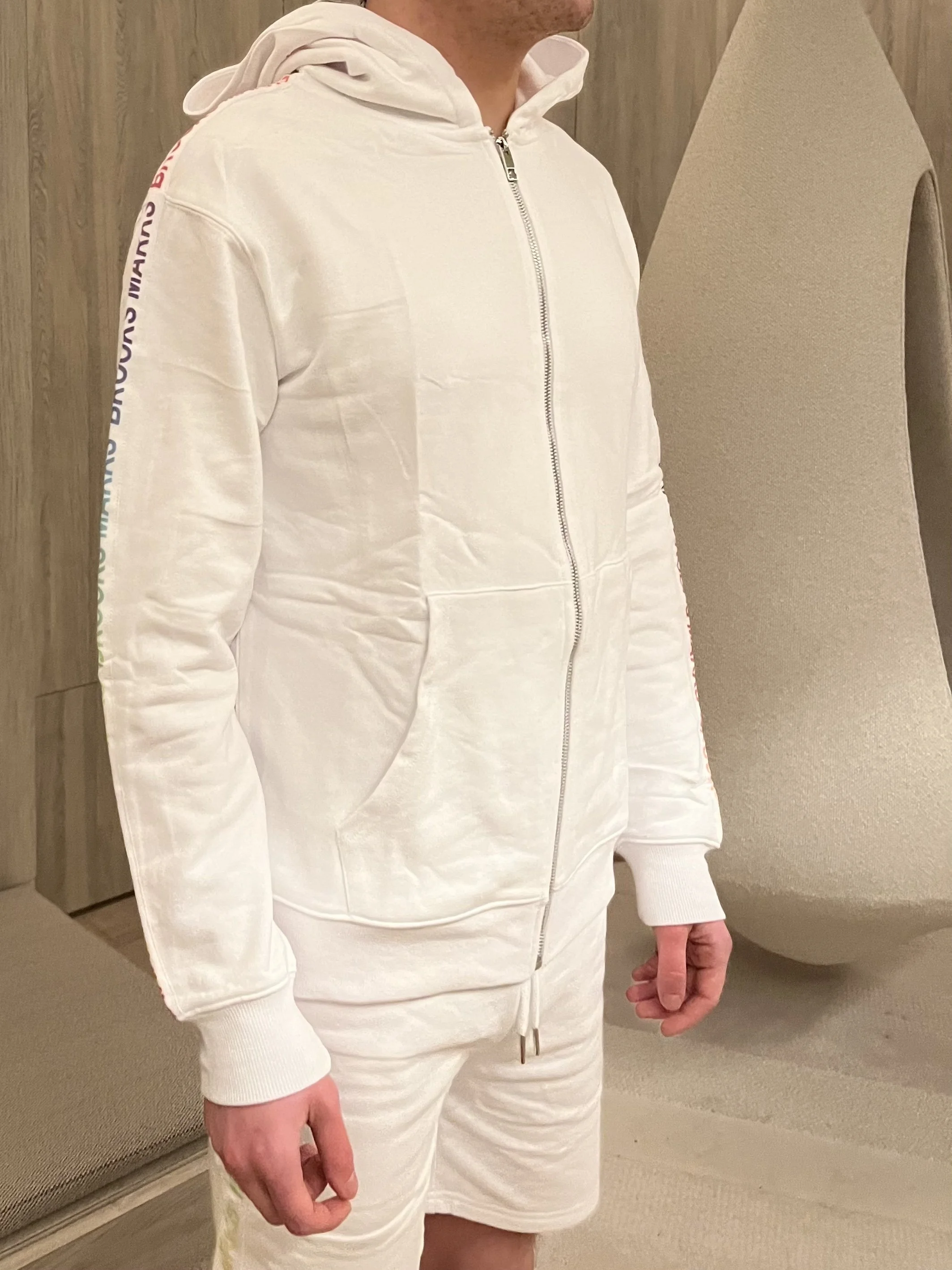

In this BLK-OUT example, the track suit is listed as 100% Cotton but contains Polyester blend in the bands, as well as Polyester thread. The result is a deep black, with white thread and a gray hue in the areas that have mixed materials. In short, Polyester doesn’t hold black.